Printing &

Signage

Digital and screen

printing onto almost

any surface

Printing

- Provided it has a flat surface and sometimes even if it doesn't, our in house equipment can print almost anything.

- Labels, Signage Boards, whether you want millions or just a few, our in house equipment can do it all !

- Need something shaped? Our laser machine can cut the product to suit.

Need some help? Call us with a wealth of industry knowledge we will find a solution.

Direct to Surface Screen Printing

Elevate your branding and design with our direct-to-surface printing services. From metal and glass to plastics and more, experience vivid and durable prints that make a lasting impact.

Explore the versatility of direct-to-surface printing for personalized products, industrial applications, and beyond. Bringing your ideas to life with precision and innovation

Versatile, Durable and High Quality Output

These are just a couple of reasons why screen printing is still as relevant today as it has always been.

- Spot Colours – Special brand colours can be replicated.

- Economies of scale – The higher the volume the lower the unit cost making screen printing perfect for industrial print applications.

- High-Density Colour – vibrant, solid colours are easily achieved Inks can also be applied thicker, resulting in long lasting, brighter and more vibrant colours.

- Versatility – Screen printing can be applied to almost all materials and provides clearer,

cleaner text. We can screen print directly to glass, lexan, polycarbonate, vinyl and sign boards

and also direct to machine parts. - Printing on metal and stainless steel

-

Screen printing is a versatile printing technique used to transfer ink onto a substrate through a mesh screen. This process is commonly employed in various industries to create screen printed components. Here’s some information about screen printed components:

-

Overview:

- Process: Screen printing involves the use of a mesh screen to transfer ink onto a substrate. The screen contains openings (mesh) that allow ink to pass through in specific areas, creating the desired design or pattern on the substrate.

-

Materials Used:

-

Substrates: Screen printing can be applied to a wide range of substrates, including paper, fabric, glass, metal, plastic, and more. The choice of material depends on the application and desired outcome.

-

Inks: Different types of inks can be used in screen printing, including water-based, plastisol, and UV-curable inks. The type of ink selected depends on the substrate material and the desired properties of the final print.

-

-

Applications:

-

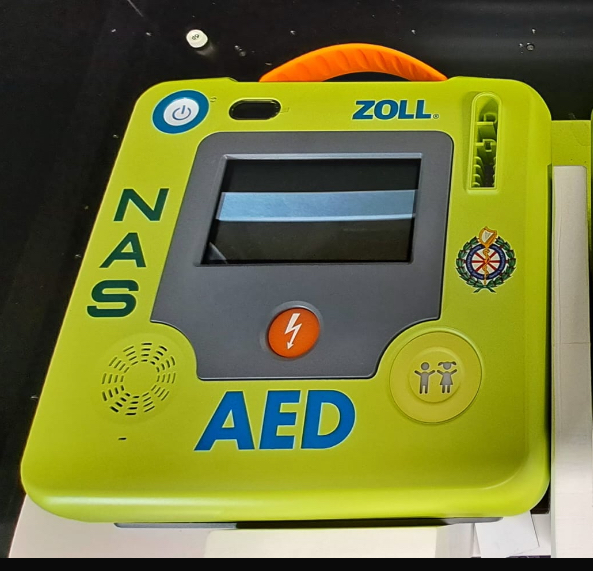

Industrial Components: Screen printing is used to mark and label various industrial components. This includes printing on control panels, electronic devices, and other components for identification and branding.

-

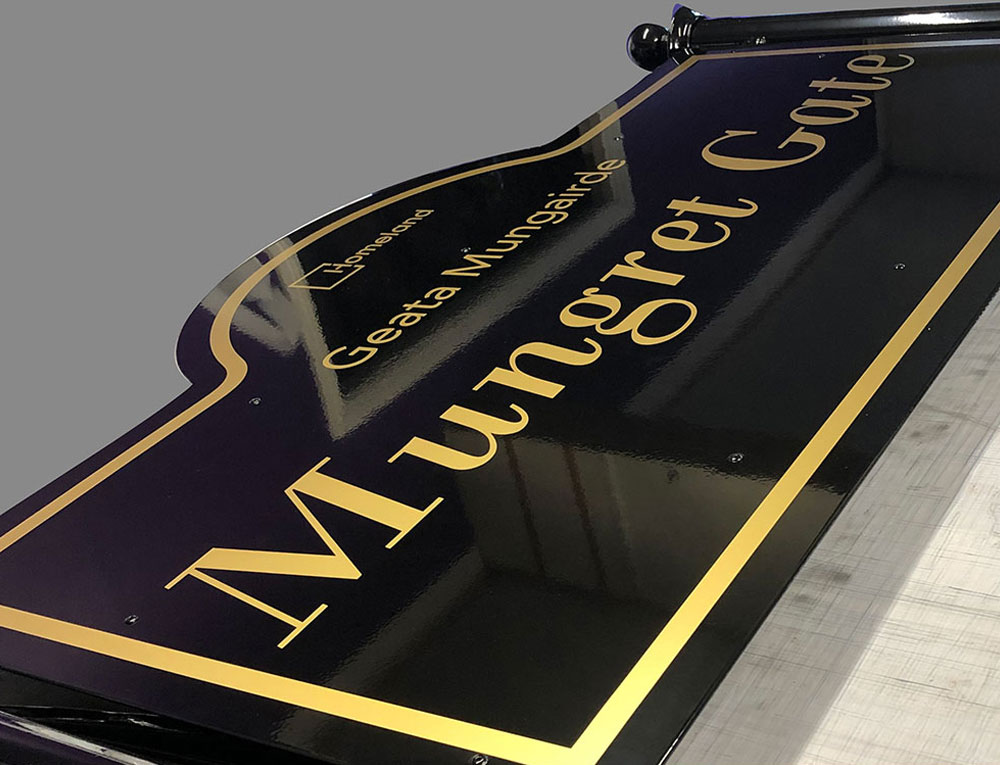

Signage and Graphics: Screen printing is employed to create durable and visually appealing graphics for signs, banners, posters, and decals.

-

Packaging: Screen printing is utilized for printing designs and information on packaging materials, including boxes, bags, and labels.

-

Circuit Boards: In electronics manufacturing, screen printing is used to apply conductive inks to create circuit patterns on printed circuit boards (PCBs).

-

-

Benefits of Screen Printing:

-

Versatility: Screen printing can be adapted to various substrates, making it a versatile option for different industries.

-

Durability: The prints produced through screen printing are often durable and resistant to wear and tear, making them suitable for industrial and outdoor applications.

-

Customization: Screen printing allows for detailed and customizable designs, making it a popular choice for creating unique and personalized components.

-

Cost-Effective: For large production runs, screen printing can be a cost-effective option, especially when the same design is applied to numerous components.

-

-

Design Considerations:

-

Color: Screen printing supports a wide range of colors. However, each color typically requires a separate screen, which may influence the production cost.

-

Resolution: Screen printing can achieve high resolutions, but intricate details may be limited compared to digital printing methods.

-

Size: The size of the screen determines the maximum print size, so consider the dimensions of the components when planning the design.

-

-

Quality Control:

-

Registration: Proper alignment and registration are crucial to ensure accurate and consistent prints, especially in multicolor designs.

-

Inspection: Quality control measures, such as visual inspection, are employed to identify and address any issues during the screen printing process.

-

In summary, screen printing is a versatile and durable method used for creating components in various industries. Whether for textiles, industrial applications, signage, or electronics, screen printed components offer a combination of customization, durability, and cost-effectiveness.

-

Electrostatic Discharge Shielding

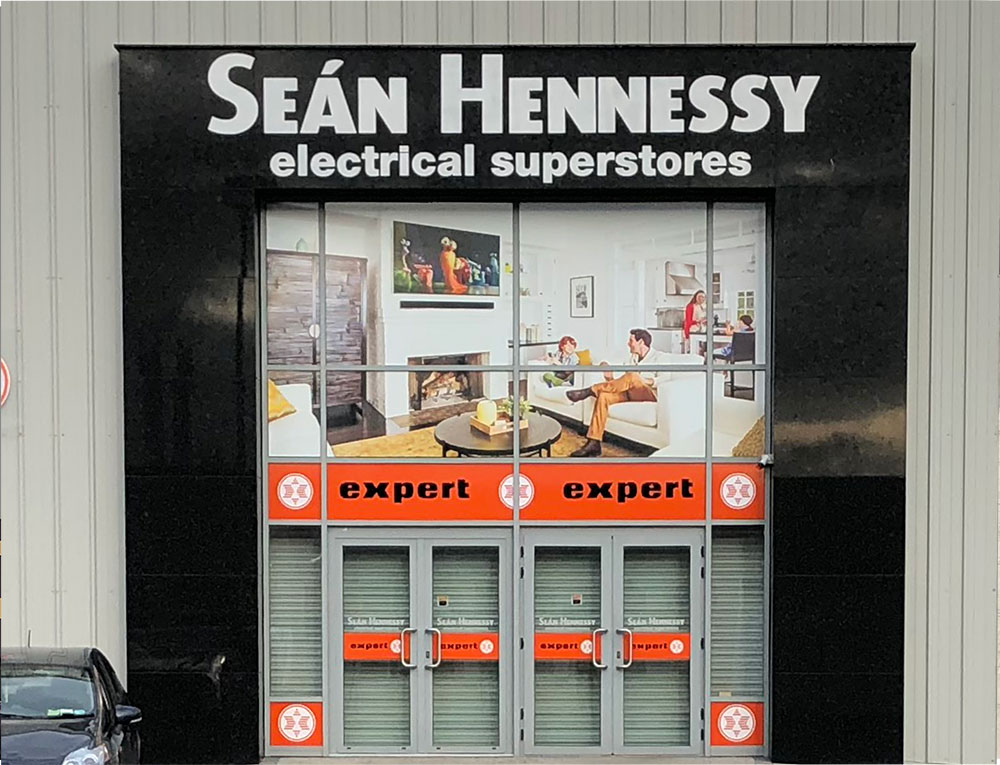

With the ability to print full colour onto long-lasting vinyls, we can virtually make signage to any size that is vibrant and colourful including the following:

- Event Signage

- Shopfront Signage

- Pull up banners

- Canvas banners.

Chapter 8 Roadwork signs

Advertising Signage

- Interior and Exterior Signs and Graphics

- Window Graphics

- Carved 3d Lettering

- Point of sale items

- Pavement Signage

- Canvas Banners

- Pull up banners

Decals

If you are branding equipment, we can supply long term decals.

We can provide artwork with consultations regarding design with our graphics team.

Labels

Whether you need large quantity, or just a few for prototyping, our design team can guide you through from concept to project completion.